It used to be that all you needed to start an edibles company was some weed, a Crockpot and a dream. Black-market edibles were relegated to occasional homemade batches of brownies or cookies with enterprising kids on tour selling gooballs or Rice Krispie treats in farmer’s market parking lots. Your experience could range from potentially transcendent to waaaaay too strong to a complete bust, leaving you cursing the creep who burned you. There was just no way to know whether that innocent-seeming glob of peanut butter Captain Crunch, marshmallows and raisins contained 50 mg of THC or 500 mg, and many people didn’t care to find out.

Lab testing edibles changed all of that and enabled multi-million-dollar infused food businesses to emerge. For the first time, it seemed, consumers could have a predictable experience, consistent from one trial to the next. But lab testing, especially at its nascent beginnings, was ill-suited to accurately determine cannabinoid content in infused foods, leaving less-sophisticated edibles makers without a way to control quality. Embarrassing episodes, like the Denver Post expose on several companies whose labels made claims not matched in reality, proved that edibles manufacturers as well as cannabis lab technicians had a lot to learn, especially in an unregulated market (like California) with no industry-wide standards governing producers or testing facilities.

SC Labs, in Santa Cruz has devoted considerable resources to developing accurate testing methods for all sorts of infused foods, which is a much more complex problem to tackle when compared with simply testing flowers or hashes.

“Edibles — especially baked goods — are a tough nut to crack,” said Josh Wurzer, co-founder, CTO and laboratory director of SC Labs. “Unlike testing flowers or concentrates, one-size-fits-all testing preparations don’t work for edibles.”

While the edibles market is a small fraction of their overall clientele, the staff at SC Labs are determined to develop analytical strategies tailored to accurately evaluate every product that ends up in their hands.

“Certain types of edibles have huge variability in their manufacturing processes,” Wurzer explained. “For every different category of edibles, we have a different prep procedure.”

Hard candy is prepared for analysis differently than baked goods, methods vary for tinctures made with alcohol versus those made with glycerin and infused olive oils aren’t treated the same as solid, dense fats like butter or coconut oil.

The potential for variables in every step of the edibles making process is large indeed, based on ingredients, dosage concentrations and cooking temperatures, making it extremely important for manufacturers to embrace lab testing, especially during the early product formulation and process standardization stages.

“If it’s something completely new that we’ve never seen before, we go through a bit of an R&D process to figure out how to best test that type of product. It happens less and less but we’re still seeing all kinds of weird stuff,” Wurzer said. “Initially, there should be a lot of testing for a manufacturer to get a handle on how efficiently the cannabinoids are being infused, what kind of variability they have from batch to batch, what kind of variability within a batch. Once you get a handle on how the whole process works, then you can do just quality control testing.”

Wurzer spends considerable time talking with edibles producers to understand their production processes as well as advising them on dosage formulas, food safety issues and proper labeling.

“A lot of the baked goods are really hard for us to standardize for the manufacturers,” he said, explaining how a certain chocolate chip cookie recipe had to be tested without the chocolate chips for the most accurate results. “We had to bake just the dough to get our validation… If one cookie has 12 chips, another has 20, and if you’re medicating the dough but not the chocolate chips, then the more chocolate chips you put in, the more you are diluting your cannabinoids.”

Unless edibles bakers plan to painstakingly dole out 10 chocolate chips to every cookie, there will always be a percentage of variation in lab-tested results, which explains why some products seem to fall short of their advertised cannabinoid content. Baked goods are especially difficult to keep consistent due to pockets of cannabutter getting spread unevenly throughout the batch. It’s not ideal to completely homogenize the dough or batters of most bakery items, since over mixing activates gluten, resulting in tough, chewy brownies or cakes with unappetizingly flat and dense textures compared to desirable fluffy, light crumbs.

“When things are made by hand, with a little more of this or a little less of that, it can swing the results dramatically,” Wurzer shared. “The thickness of icing can change the cannabinoid content by huge swings.”

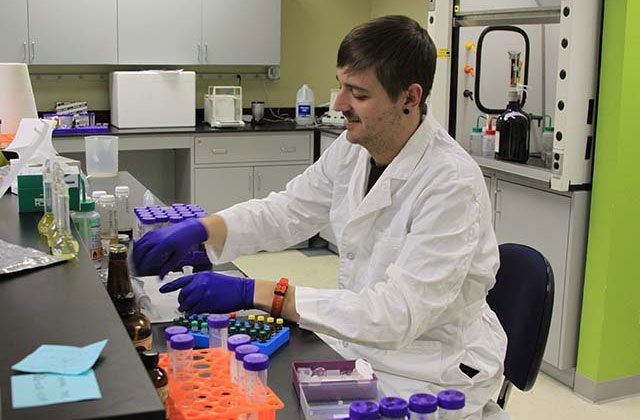

Mackenzie Whitman, lab technician, prepares samples for analysis.

After an edibles maker drops off their product at SC Labs, it’s photographed and logged into their system. Then it’s pulverized in a bead beater (if necessary) until it’s reduced to a powder. Depending on the solubility of the product, the pulverized powder is next dissolved into either hexane or methanol. That solution is then diluted several times until it gets into a range of concentration where the instruments can best read it. Then the solution is run through the high pressure liquid chromatography (HPLC) machine and test results are generated.

Co-founder, CTO and lab director of SC Labs, Josh Wurzer, stands next to one of the HPLC machines used for potency analysis.

The HPLC reveals the levels of THCa, the acidic precursor to psychoactive THC, determining if an infusion was efficient and properly decarboxylated, as well as levels of CBN, the sedating byproduct of THC degradation. Too much CBN can signify cooking temperatures that went too high for too long. You will also discover the levels of a full range of lesser-known cannabinoids like THCV and CBG, and terpene analysis is available for extracts and flowers.

SC also tests for microbial contamination, which can help manufacturers determine shelf life and long-term product stability. Screening products for salmonella, shigella and e. coli protects patient health and the reputation of the entire industry.

“There’s a different set of microbial concerns when you’re making a food product,” Wurzer said. “And we’ve found contaminated products, not alarmingly high numbers, but yes, it happens.”

Kyle Boyar, Lab Technician, holds several plates used to grow fungal and bacterial cultures extracted from samples that are then used to perform microbiological analysis.

Despite what the layman might think, scientific processes are not infallible.

“No analytical test is perfect, but all of our edible tests have less than 5 percent variability at this point,” Wurzer said.

An industrious intern who was tasked with testing recipes made lab procedures with such high levels of accuracy possible.

“She’d do the whole process just like a manufacturer would” Wurzer recalled. “She’d infuse butter with a known amount of cannabinoids and bake that cookie. She did it every day for months. It was a fun project, and it really gave us a handle on how to best test every type of edible.”

By carefully validating their processes, SC Labs is confident that they are on their way to developing standards that could be implemented industry-wide.

“THC potency testing is more of a measure of quality for the other products like flowers or waxes, but for edibles it’s a safety test,” Wurzer said, relating how vitally important it is for consumers to be able to judge their dose correctly. “You have a right to know what type of experience to expect.”